Product Engineering

Agile isn't just for digital anymore.

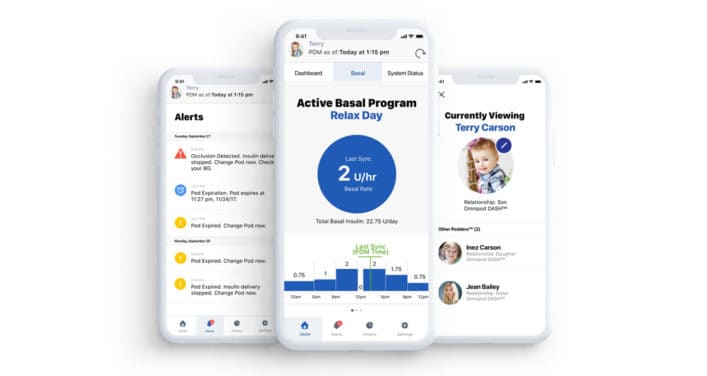

The world isn’t short of great ideas. It’s short of well-executed ones. THRIVE bridges that gap, applying agile engineering practices to manufacture products for the real world. Our product engineering teams work iteratively with in-house researchers, UX specialists and designers to champion the design intent and bring products to market as envisioned.

At THRIVE, we will work with you to help turn great ideas into the exciting, innovative products your customers don’t even know they want yet (but will!)

What is Product Engineering?

Product engineering means designing and pricing products, translating your ideas into prototypes, preparing products for volume manufacturing and validating and testing the design. Every step is done with an eye toward helping you comply with regulatory requirements.

The experienced product engineering professionals at THRIVE handle every step of the process, serving as a valuable resource for you.

Conceptual Engineering

In the conceptual engineering phase, we are focused on designing your product, exploring manufacturing feasibility and pricing options. This stage includes defining requirements, establishing the system architecture, designing complex mechanisms, selecting and packaging electronic components, ergonomic rigs and creating breadboard and concept models.

Design for Manufacturing

Taking the designs created during the conceptual engineering phase, THRIVE next works to optimize those designs. We’ll identify what needs to happen to produce your product and define a path to get to production. This step involves assessing the manufacturability of the product, designing the mechanical components, designing plastic injection molding parts, geometric-dimensioning and tolerancing, selecting materials and analyzing costs, and preparing manufacturing drawings.

Proof of Concept

We won’t know if a product design is solid until we can actually see and use it, so we also build out prototypes to demonstrate product functionality to key stakeholders. THRIVE has the capability for rapid prototyping (SLA/FDM), and services include experience demonstrators, usability models and pilot builds.

Design Validation and Testing

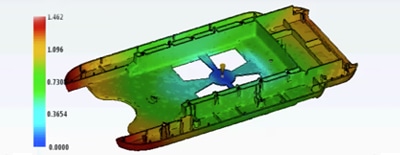

When you’re ready to move into production, THRIVE helps by using validation techniques to test, refine and verify new products before they are released for manufacturing. We’ll conduct failure modes and effects analysis (FMEA), finite element analysis (FEA), thermal analysis, risk analysis (FMEA and design reviews), verification and validation analysis. This step also includes simulations including injection molding simulation and mechanical event simulation.

Regulatory and Process Experience

Our product engineers understand the nuances of regulatory rules and regulations, regulatory agencies’ processes and standards, and we’re ready to help you develop strategies to meet those challenges and nuances head-on.

Our services include project and risk management, and product and system commercialization (phases & gates). We will also help you manage the RFQ/RFP process, Finally, we are adept at handling supplier and quality management, as well as safety and regulatory process management.

How THRIVE’s Product Engineering Services Can Help Your Company

You need an experienced partner to handle product engineering for you – let THRIVE be that partner.

Our product engineering team has been involved in some pretty spectacular products. Don’t just take our word for it though – scroll down to check out the case studies below to learn more about how our product engineering expertise has helped companies bring their ideas to life.

-

Conceptual Engineering

Our integrated team approach allows us to fail fast and mitigate risk since we focus on product design as well as feasibility of manufacturing and appropriate pricing.

- Requirements Definition

- Systems Architecture & Design

- Complex Mechanism Development

- Electronic Component Selection & Packaging

- Ergonomic Rigs

- Breadboard & Concept Models

-

Design for Manufacture

We use a rigorous process to optimize designs, prepare a product for volume manufacturing and define the total path for production.

- Manufacturability Assessment

- Mechanical Component Design

- Plastic Injection Molding Part Design

- Geometric Dimensioning & Tolerancing (GD&T)

- Materials Selection & Costing Analysis

- Manufacturing Drawings

-

Proof of Concept

We demonstrate and prove the feasibility of product concepts by building out "works like/looks like" prototypes that demonstrate the overall experience to key stakeholders.

- Experience Demonstrators

- Proof of Concept Prototypes

- Rapid Prototyping (SLA/FDM)

- Usability Models

- Pilot Builds

-

Design Validation & Testing

We help you navigate the transition from development to production using validation techniques to test, refine and verify products prior to release for manufacture.

- Failure Modes & Effects Analysis (FMEA)

- Finite Element Analysis (FEA)

- Injection Molding Simulation

- Mechanical Event Simulation

- Thermal Analysis

- Risk Analysis (FMEA, Design Reviews)

- Verification & Validation Analysis

-

Process & Regulatory

We're deeply experienced at interpreting regulatory schemes, agencies, rules, standards and procedures and developing strategies to help teams meet their goals.

- Project & Risk Management

- Product & System Commercialization (Phases & Gates)

- RFQ/RFP Process Management

- Safety & Regulatory Process Management

- Supplier & Quality Management